FDM Filaments & What the consumer should know! – HoodBilly Haven Style

Alright, let’s talk filaments, HoodBilly style. First of all, I too have watched my fair share of YouTube Videos. I’ve read a ton! But let me tell you somethin’, none of that book learnin’ replaces gettin’ your hands dirty. You gotta play with the materials, test ’em, and yes, sometimes you gotta waste a little to learn a lot. I’ve been at this for about three years now, seen my fair share of good and bad filaments, good and bad printers, from all over the globe.

Now, they say filaments go bad, and they ain’t wrong. Moisture can be a problem, but it ain’t as big a deal as some folks make it out to be. It’s tough to get plastics and polymers truly “wet,” but location matters. You live in Florida, some humid, tropical place? You better store your filament proper, airtight containers, desiccant packs, the whole nine yards. But up here in the North Woods, where winter sucks the moisture outta the air like a hound dog on a ham bone, storing open filament on a rack on the wall ain’t usually a problem.

Now, let’s get down to the nitty-gritty of filament types, kinda like choosin’ the right tool for the job. You got your everyday workhorse, PLA (Polylactic Acid). It’s like the duct tape of 3D printing, easy to use, biodegradable, good for prototyping and general-purpose prints. It comes in a rainbow of colors, too, so you can get real fancy with it.

Then there’s ABS (Acrylonitrile Butadiene Styrene), tougher than PLA, more heat-resistant, good for parts that need to withstand a little wear and tear. But it can be a bit trickier to print with, prone to warping if you ain’t careful. It’s like that old reliable pickup truck, gets the job done, but needs a little more TLC.

Now we’re gettin’ into the good stuff. PETG (Polyethylene Terephthalate Glycol), it’s like the best of both worlds, combines the ease of printing of PLA with some of the strength and durability of ABS. It’s also food-safe in some formulations, which is handy.

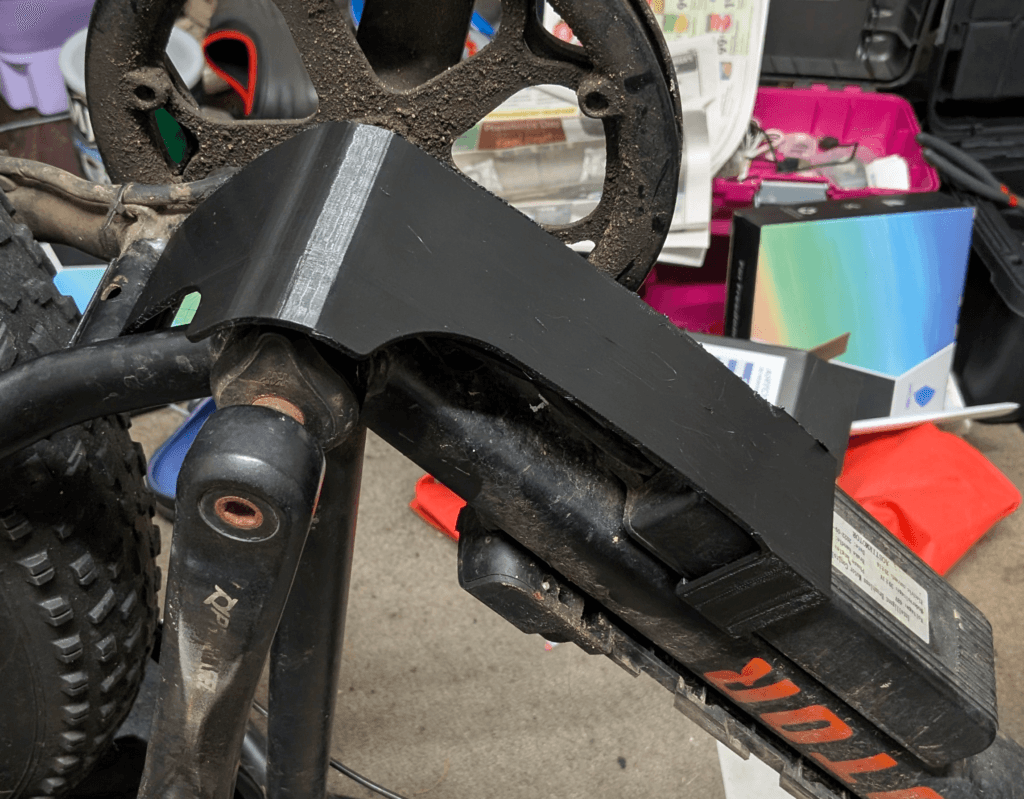

Then you got your specialty filaments, the real high-falutin’ stuff. TPU (Thermoplastic Polyurethane), that’s your flexible filament, like rubber. Great for gaskets, phone cases, anything that needs to bend and flex. And then there’s STTPU (Semi-Tough Thermoplastic Polyurethane), a stiffer variant that bridges the gap between rigid and flexible.

For the real heavy-duty stuff, you got PEEK (Polyetheretherketone). This stuff is seriously tough, heat-resistant, chemical-resistant, used in aerospace and medical applications. It’s like the titanium of filaments, but it requires specialized high-temperature printers.

And we can’t forget about the reinforced filaments. Carbon Fiber infused filaments add strength and stiffness, perfect for structural parts. It’s like rebar in concrete. Glass-filled filaments also add strength and can improve dimensional accuracy. And even metal-infused filaments, which contain powdered metal, can create parts with a metallic look and feel, and sometimes even be post-processed to look like solid metal. It’s like havin’ a little bit of blacksmithin’ in your 3D printing.

So, there you have it, a little HoodBilly wisdom on filaments. Remember, it’s not just about readin’ and watchin’, it’s about doin’. Get out there, experiment, and find what works best for you.

For an Extensive look at Filaments, check out this guide.

Leave a Reply

You must be logged in to post a comment.