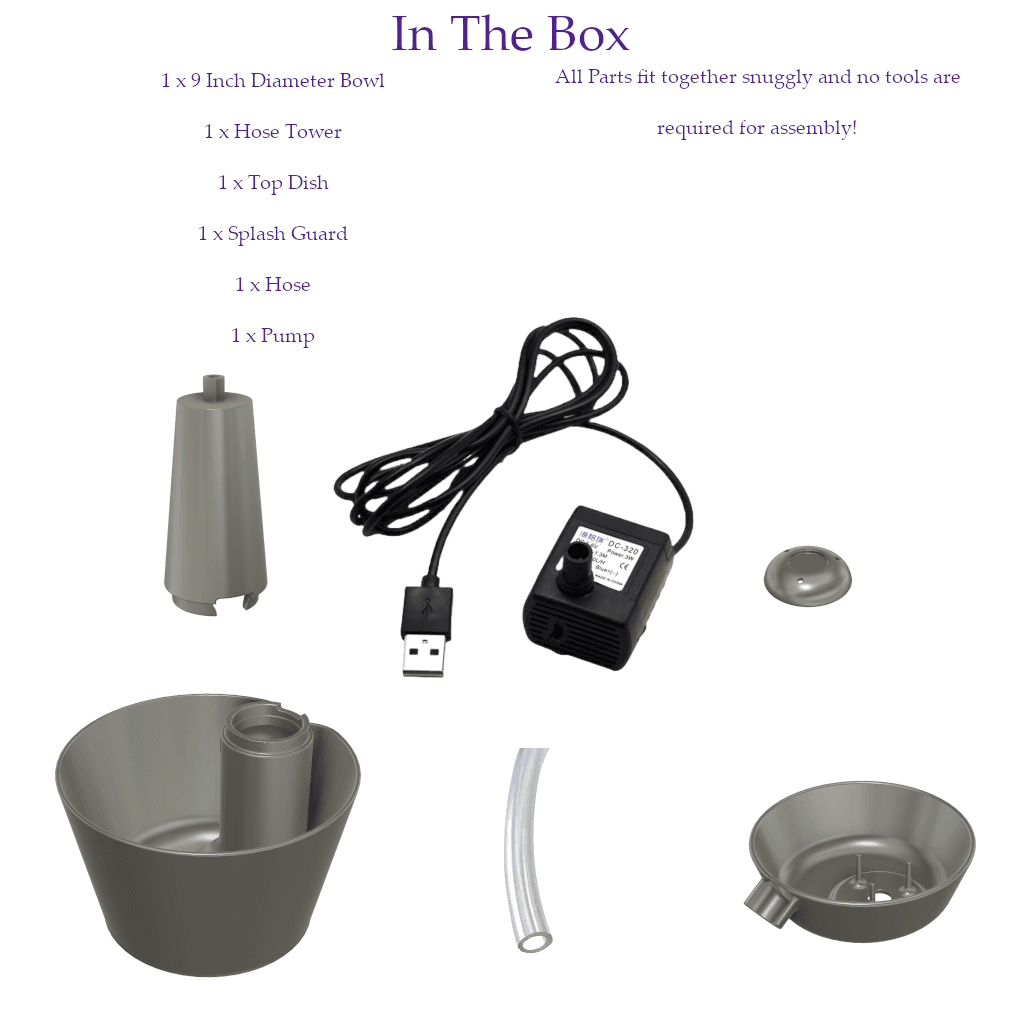

From Concept to Creation: The 6-Day Journey of a Custom V2 Dog Auto Water Bowl

The Inspiration Behind the Design

The inception of the custom V2 dog auto water bowl arose from a keen understanding of the challenges encountered by pet owners using traditional water bowls. Standard dog water bowls often present a myriad of issues, including frequent spills, lack of clean water accessibility, and difficulty in maintaining proper hydration for active pets. Observing these common concerns led to the realization that a more innovative solution was necessary to enhance the daily feeding routines of dogs and their owners alike.

Pet owners have expressed their frustration with traditional bowls, which can quickly become unclean and require constant refilling, particularly in households with multiple pets. This was a significant driver behind the design initiative. The goal was to create an automatic water bowl that would not only hold an adequate amount of water but also ensure that it remains fresh and uncontaminated. Feedback from dog owners highlighted the need for features such as easy cleaning mechanisms, adjustable water levels, and a design that could prevent spills while being aesthetically pleasing in a home environment.

To effectively address these concerns, the design process involved close collaboration with pet owners to gather detailed insights into their needs. Identifying the need for a bowl that could accommodate both small and large breeds without compromising performance was crucial. This led to the incorporation of innovative features like a filtration system, which continuously provides clean water, and a spill-proof design that ensures peace of mind in daily use. Consequently, the custom V2 dog auto water bowl emerged as a direct response to the challenges faced by dog owners, ultimately embodying a commitment to improving both functionality and user experience in pet care.

The Design Process: Concept to 3D Model

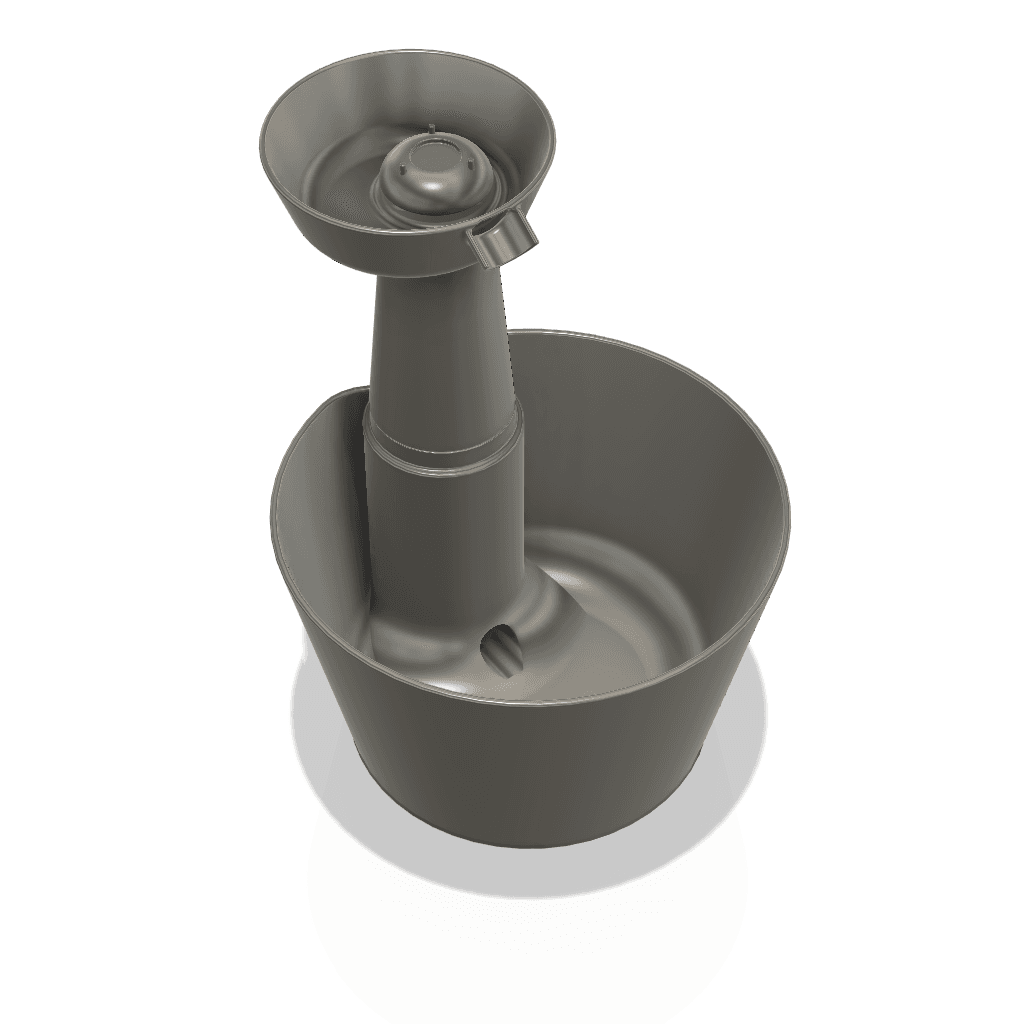

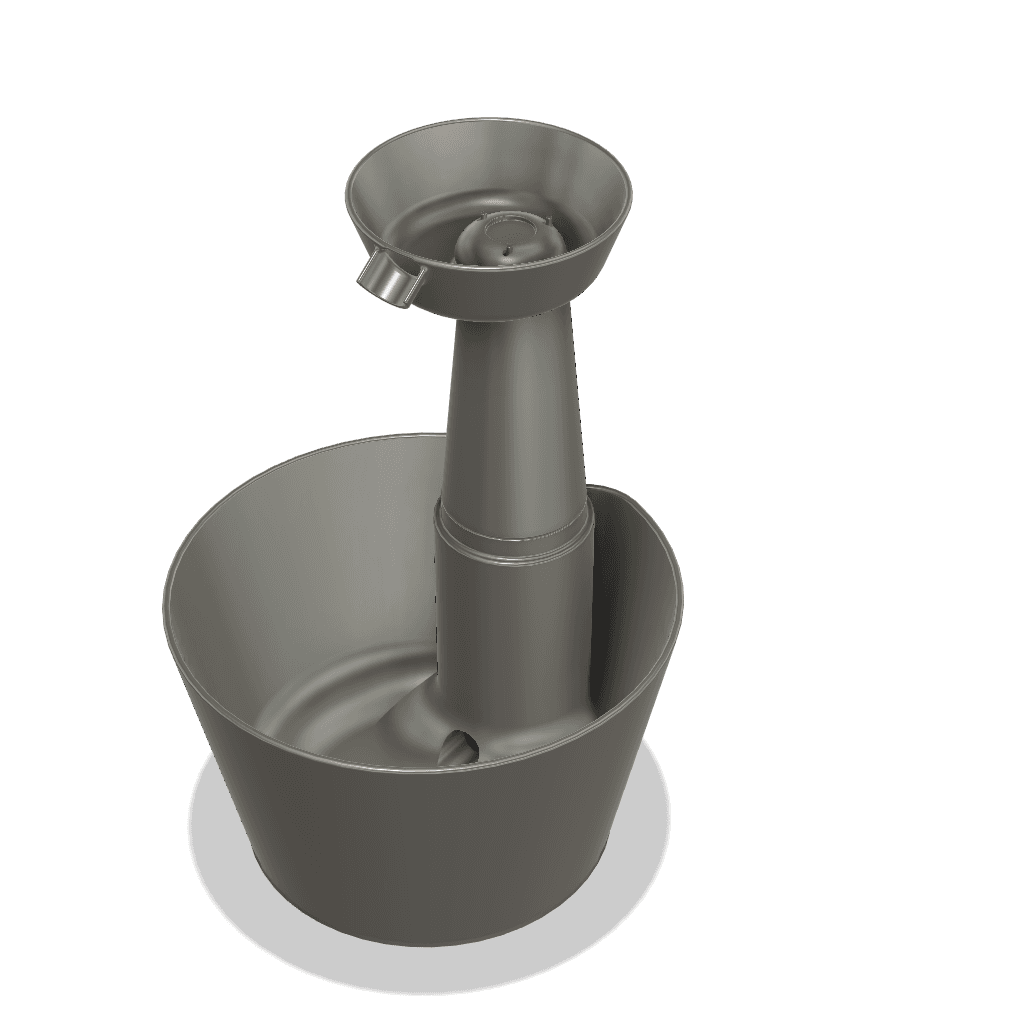

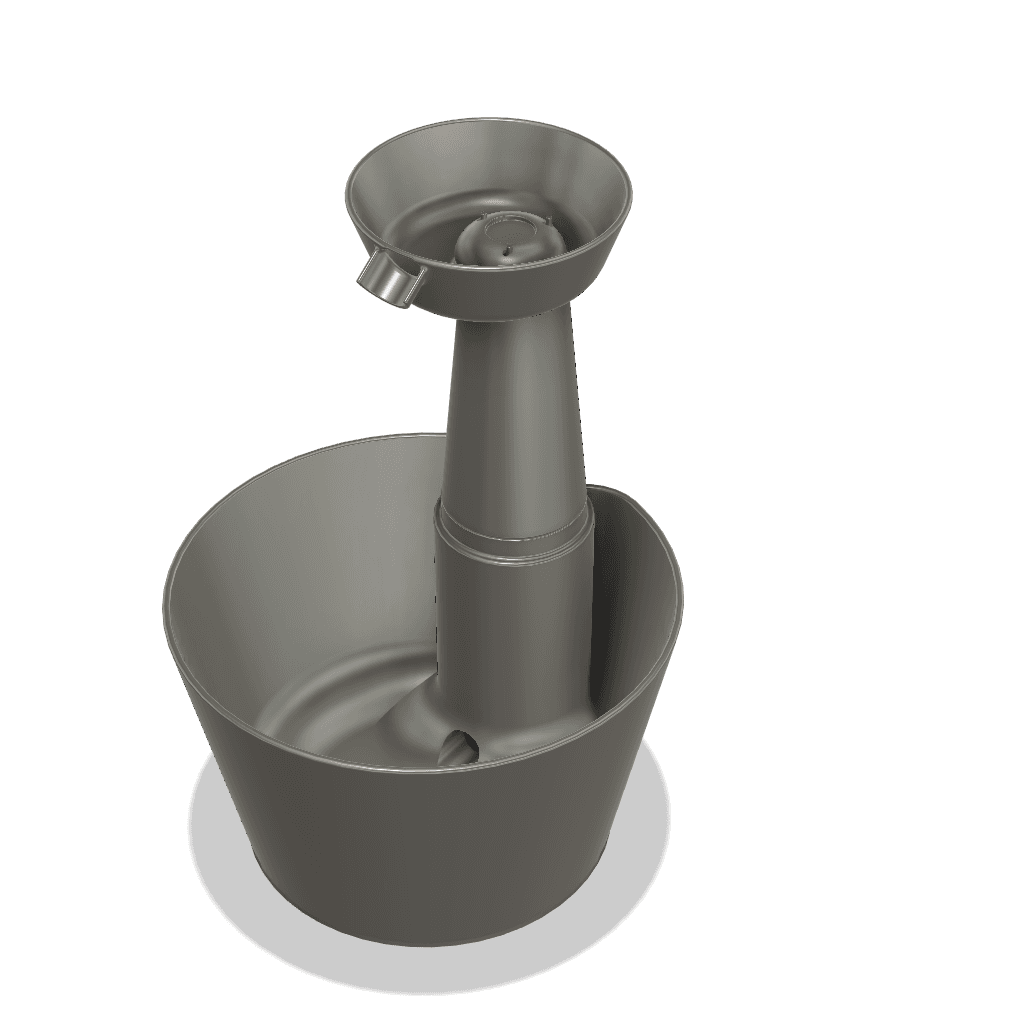

The design of a custom V2 dog auto water bowl is a meticulous process that begins with the initial concept derived from inspiration. Once the concept is established, the focus shifts to developing a detailed 3D model using advanced computer-aided design (CAD) software such as SolidWorks or AutoCAD. These tools facilitate the creation of intricate designs that balance both form and functionality. The software enables designers to visualize the bowl’s structure, ensuring that every element is precisely crafted to meet the intended specifications.

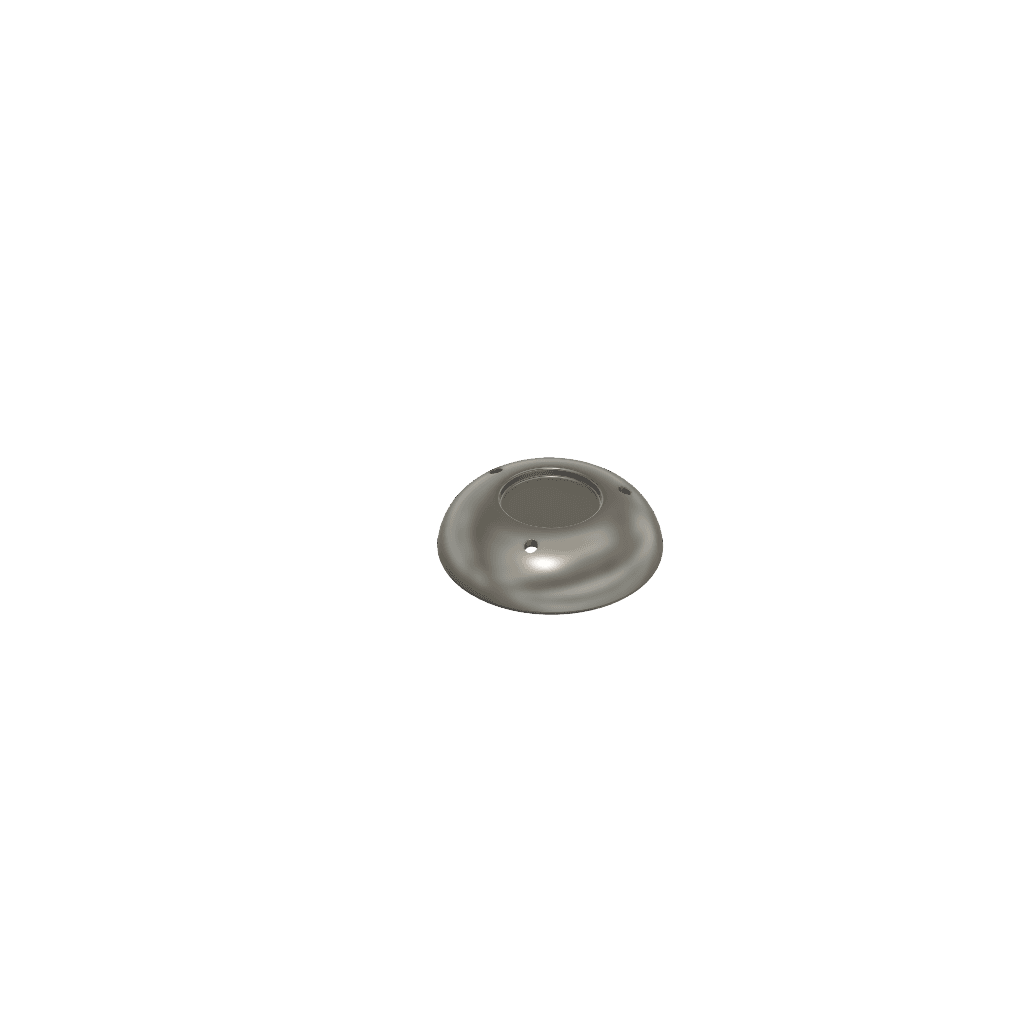

One of the critical aspects of this design process is the incorporation of a swiveling top dish. This innovative feature allows for controlled water flow, which is essential for maintaining the bowl’s functionality. The challenge lies in ensuring that this mechanism operates smoothly and efficiently, thus preventing water spillage while allowing easy access for pets. Designers meticulously analyze the rotation mechanics and spatial relationships in the 3D model to achieve optimal performance.

Customer feedback plays a pivotal role at various stages of the design process. Engaging with potential users enables the integration of practical insights, helping refine the model to suit specific needs. Iterative reviews and adjustments based on this feedback are essential, ensuring that the final product aligns with user expectations. Moreover, the importance of prototyping cannot be overstated. Creating a physical prototype allows designers to test the application of the 3D design in real-world scenarios. This step is crucial for identifying potential issues before mass production, ultimately facilitating a smoother transition from concept to completion within the compressed timeline.

Production: 3D Printing the Custom Bowl

The production of the custom V2 dog auto water bowl marks a significant step in the overall journey from concept to creation. The choice of 3D printing as the manufacturing process was deliberate, allowing for personalization and efficiency. For this project, PLA (Polylactic Acid) filament was chosen due to its durability and safety, particularly important in creating products for pets. PLA is a biodegradable plastic derived from renewable resources, making it an environmentally friendly option, while also providing the required strength for everyday use.

The printing was executed on a K3 Combo printer, specializing in high-precision tasks. The entire print time was approximately 62 hours, reflecting a careful balance between detail and durability. Each layer added during the printing process demands meticulous attention to detail, as any deviations could compromise the bowl’s structural integrity or function. This duration not only encompasses the physical printing but also the pre-configuration and post-processing of the 3D printed parts, which are essential for achieving the final aesthetic and practical quality.

Throughout this phase, several challenges emerged, particularly regarding the sourcing of high-quality PLA filament. Ensuring that the materials met the necessary safety standards was imperative, especially given that the final product will be used by dogs frequently. Moreover, maintaining a consistent print quality necessitated strict quality control measures. Regular checks were made to prevent issues such as warping or misalignment, which are common pitfalls in 3D printing.

Ultimately, the production phase of the custom dog water bowl through 3D printing exemplifies how strategic choices, such as material selection and quality assurance processes, play critical roles in bringing a well-conceived design to life. This commitment to quality ensures that the final product aligns with both functionality and safety standards, resulting in a durable bowl that caters effectively to the needs of pet owners.

Bringing the Product to Market: Delivery and Custom Orders

After the successful production of the Custom V2 Dog Auto Water Bowl, the focus shifts towards the crucial process of delivering the product to the customer. Ensuring a seamless transition from production to delivery involves meticulous planning and effective logistical strategies. The bowl, designed with the latest 3D printing technology, undergoes quality checks before it is packaged securely for shipment. This guarantees that the final product arrives in perfect condition, ultimately enhancing customer satisfaction.

For customers desiring personalized pet accessories, the world of custom 3D-printed products opens up exciting possibilities. The customization options are plentiful, allowing for various designs and modifications tailored to meet specific needs. This includes choices in color, size, and even unique engraving options, providing a distinctive touch that reflects the pet’s personality. To facilitate these custom orders, a streamlined process has been established. Customers are encouraged to submit their design ideas directly through an online platform where they can interact with specialists who will guide them through the available options, ensuring that their vision comes to life.

Our commitment to fast turnaround times sets us apart from competitors. Once a custom design is approved, it typically enters production with a swift turnaround, allowing for minimal waiting time. The efficiency in our operations means that pet owners can quickly receive their unique items, keeping their furry friends happy and hydrated without unnecessary delays. As a call to action, readers are invited to explore the world of custom 3D-printed pet accessories. Your ideas could materialize into a functional and elegant design that enhances both you and your pet’s experience. To begin your journey, simply reach out and share your requirements and preferences. Let’s embark on creating a one-of-a-kind bowl tailored for your beloved companion!

Leave a Reply

You must be logged in to post a comment.