Is Metal 3D Printing Coming to Your Desktop? Velo3D’s Gamble Might Hold the Answer

The 3D printing world is abuzz. Velo3D, a company known for its massive, industrial-scale metal 3D printers, just underwent a dramatic restructuring. New leadership, a fresh strategy, and a desperate fight for survival – could this shakeup be the catalyst that finally brings metal 3D printing to the masses?

Imagine a world where you could print complex metal parts, tools, or even jewelry right from your home. No more waiting for shipments, no more expensive outsourcing. This future felt distant just a few years ago, but Velo3D’s recent moves might be a sign that the tides are turning.

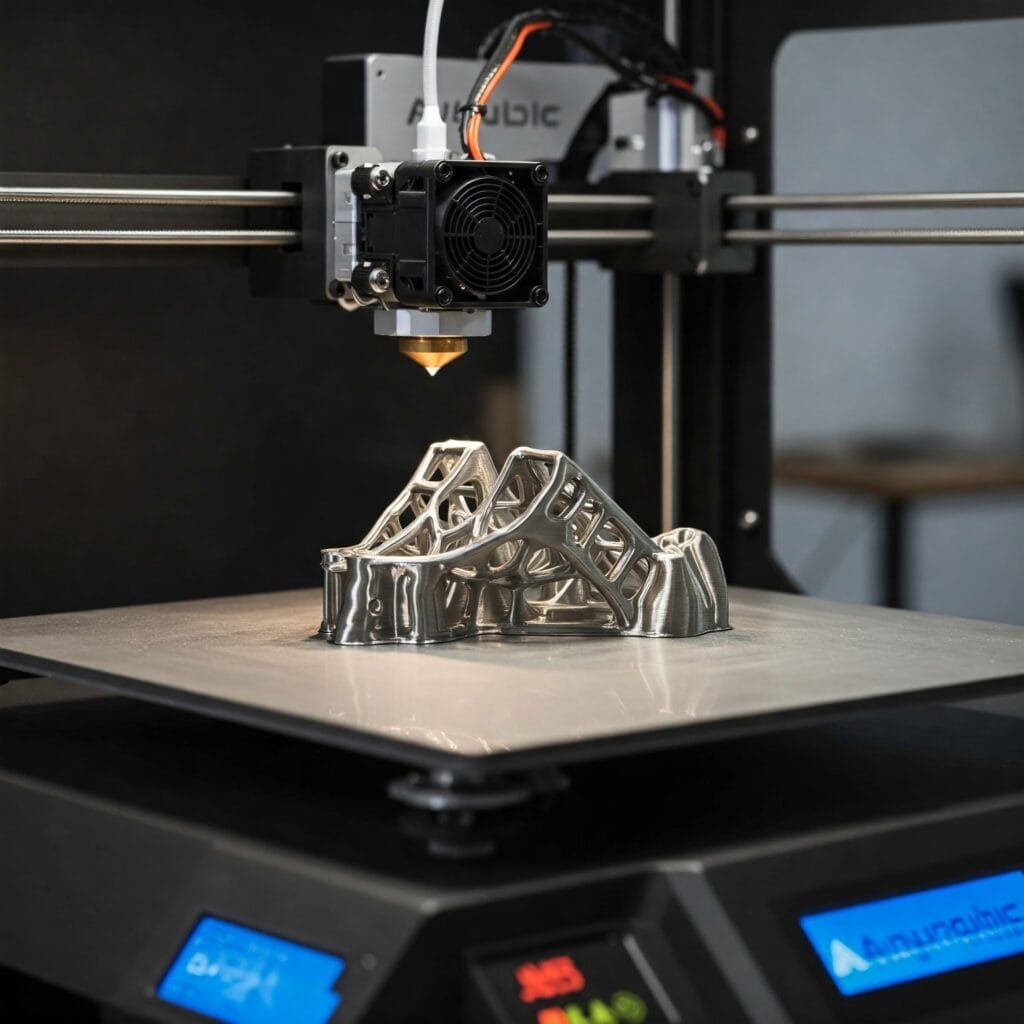

Photo From Velo3D.com

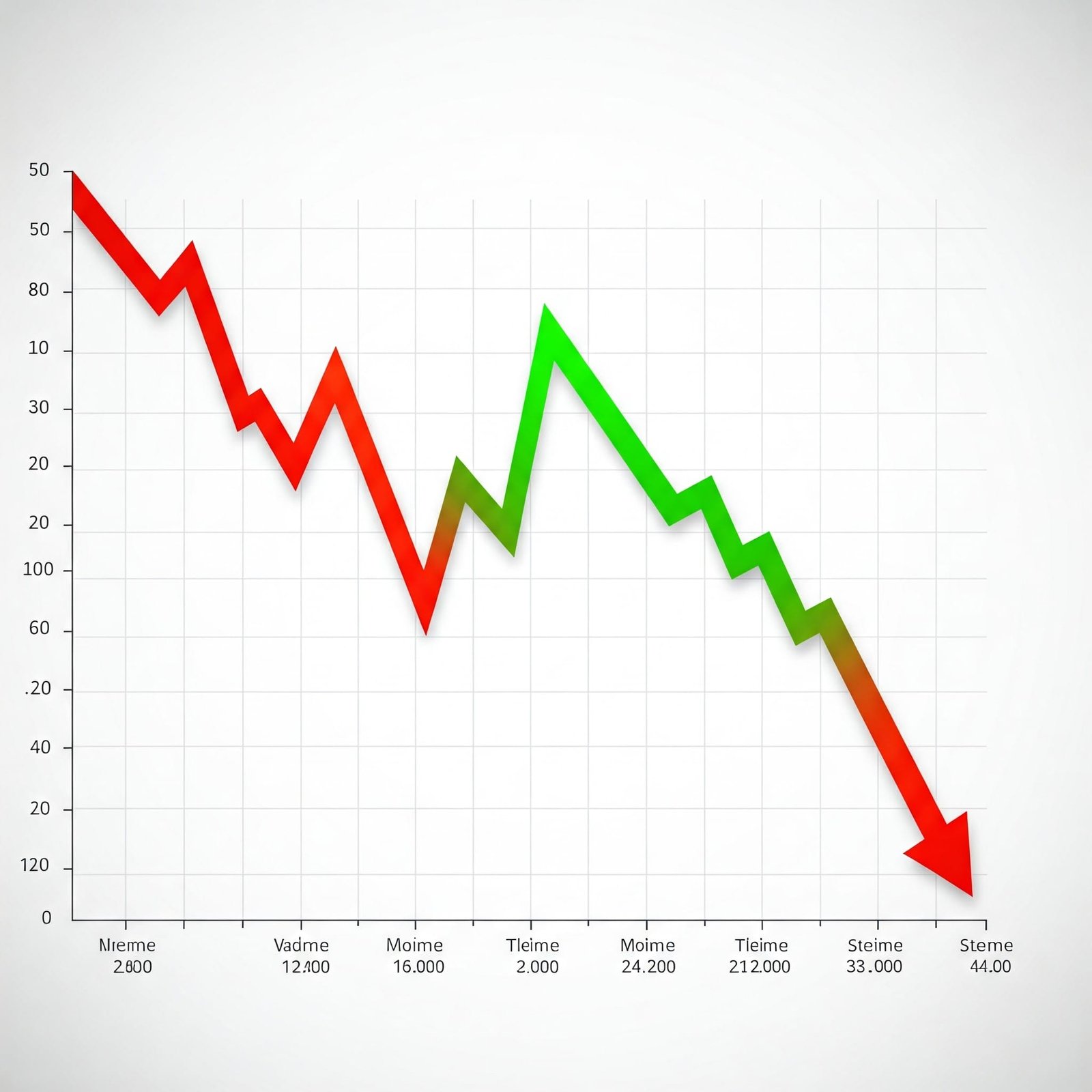

Velo3D’s Rollercoaster Ride

Velo3D has been through the wringer. Financial struggles, a plummeting stock price, and a near delisting from the New York Stock Exchange painted a grim picture. But like a phoenix rising from the ashes, they’ve emerged with a new CEO and a bold plan.

Their strategy? Target the lucrative defense, aerospace, and space industries while simultaneously exploring new revenue streams. This could mean anything from selling 3D printed parts to offering design services or even – dare we say it – developing smaller, more affordable metal 3D printers for the consumer market.

The Desktop Metal Dream

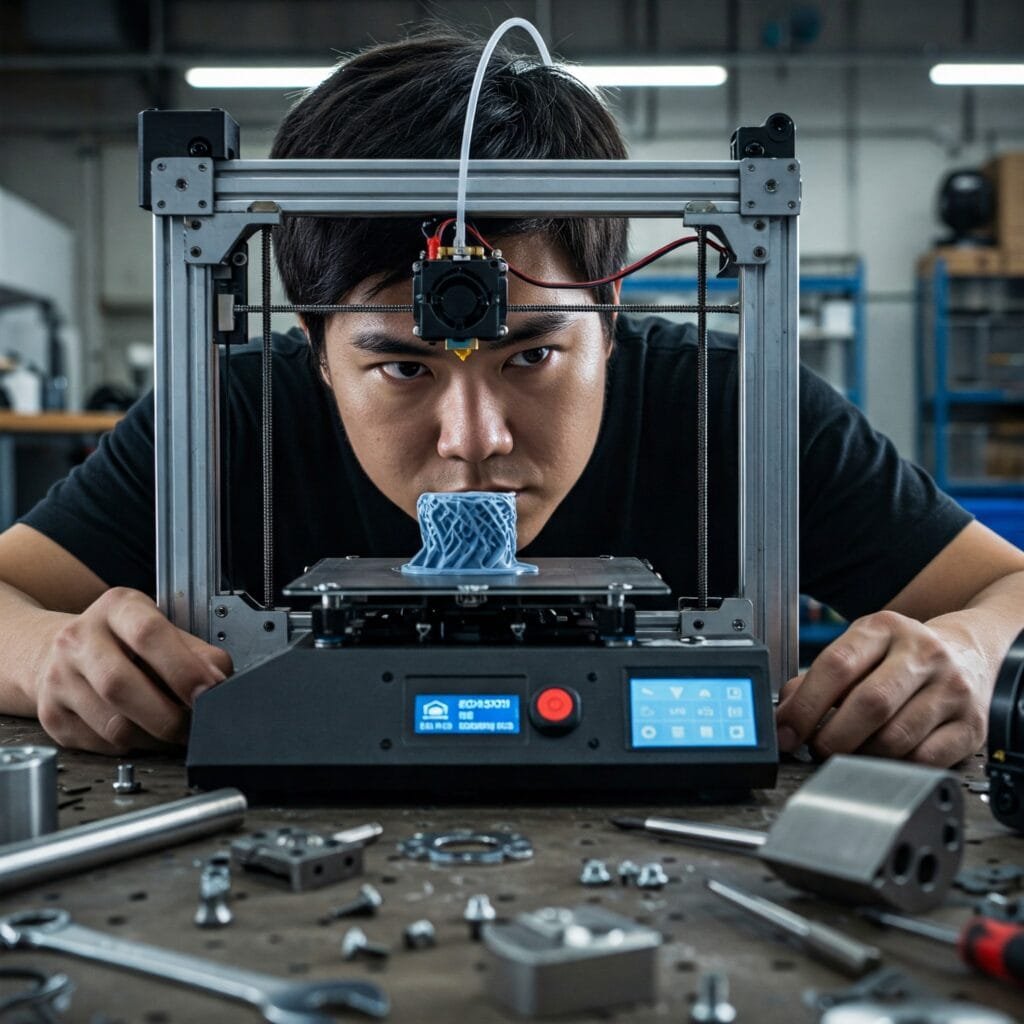

The idea of “desktop metal” has been tantalizingly close for years. Companies like Desktop Metal (ironically, a company Velo3D once tried to acquire) have made significant strides in miniaturizing metal 3D printing technology. But the high costs and complex processes have kept it out of reach for most hobbyists and small businesses.

Could Velo3D be the disruptor we’ve been waiting for? Their expertise in large-format metal printing could give them a unique edge in developing compact, user-friendly systems. Imagine the possibilities:

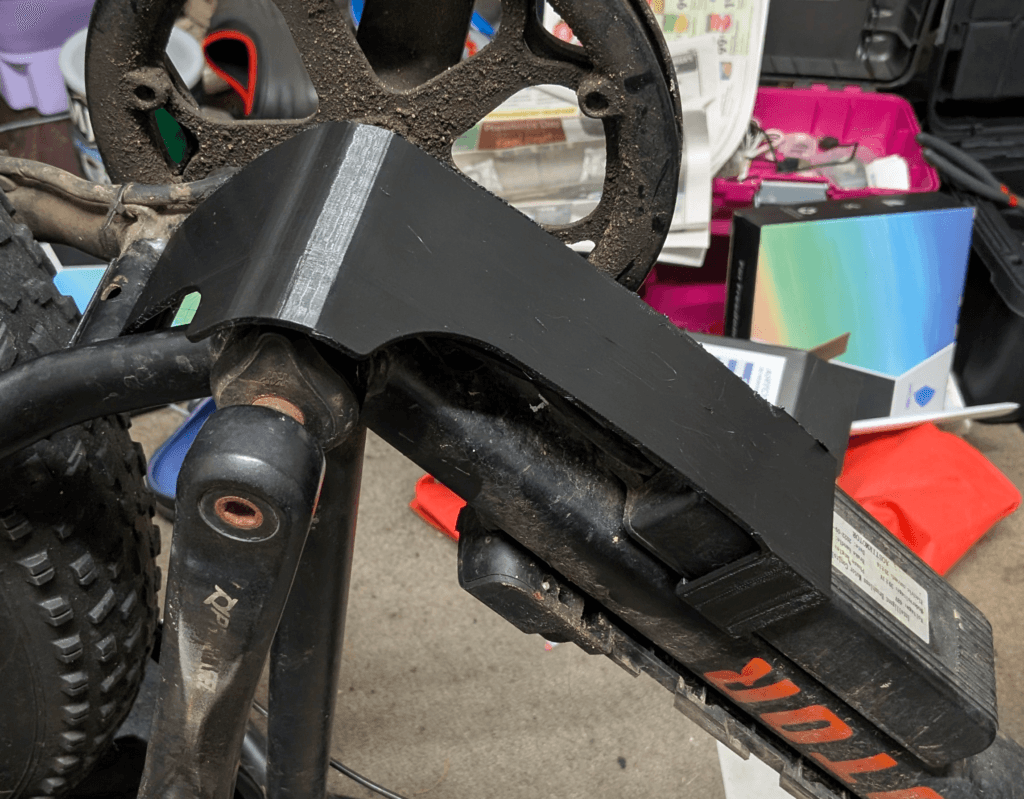

Small businesses prototyping and producing metal components in-house.

DIY enthusiasts crafting custom metal tools and hardware.

Artists and designers creating intricate metal sculptures and jewelry.

Our Opinion:

“And you know what really gets us fired up? The thought of metal 3D printing breaking free from those massive factories and landing right here on our workbenches. Imagine the day when we can ditch the welding torches and just… print those intricate metal parts we’ve been dreaming of. No more sparks, no more fumes, just pure design freedom!

Okay, maybe we’re getting a little ahead of ourselves. But hey, a company can dream, right? We’re keeping a close eye on those advancements in desktop metal, and the moment it becomes viable, you better believe we’ll be the first ones to jump on board. Just picture it: custom tools, one-of-a-kind jewelry, intricate prototypes… all printed right here in our little workshop.

It might sound like science fiction now, but we’re convinced that this is the future of making. And we’re not just gonna sit around and wait for it to happen – we’re gonna be a part of it, pushing the boundaries and making that dream a reality.”

Challenges and Uncertainties

Of course, bringing metal 3D printing to the desktop won’t be easy. Safety concerns, material costs, and the technical complexity of the process are significant hurdles. But if any company has the potential to overcome these challenges, it might be Velo3D.

Their new leadership seems determined to innovate and push the boundaries of what’s possible. Whether this leads to a metal 3D printer in every home remains to be seen, but one thing is certain: the future of metal additive manufacturing is about to get a whole lot more interesting.

Keep your eyes peeled. The metal 3D printing revolution might be closer than you think.

Leave a Reply

You must be logged in to post a comment.