The 3D Printing Revolution: A Journey Through My Experiences

Introduction to 3D Printing

3D printing, also known as additive manufacturing, has evolved significantly since its inception in the 1980s. Initially, it was a technology primarily reserved for industrial applications and high-end prototyping. Early adopters faced numerous challenges, including high costs, limited materials, and complex software requirements that rendered this innovative technology inaccessible to the average consumer. However, over the past couple of decades, 3D printing has transitioned into a more user-friendly and versatile technology, gaining traction among hobbyists, educators, and small businesses alike.

The evolution of 3D printing is marked by advancements in technology that have dramatically reduced the cost of entry for enthusiasts and inventors. The introduction of affordable desktop 3D printers, such as fused deposition modeling (FDM) machines, has made it possible for anyone to create three-dimensional objects from the comfort of their home. In addition, the development of open-source software has encouraged collaboration and innovation within the 3D printing community, fostering a culture where knowledge and resources are freely shared.

Furthermore, recent improvements in speed and efficiency have further propelled the adoption of 3D printing across various sectors. Enhanced precision and the ability to work with a growing array of materials, including plastics, metals, and even bio-materials, have expanded its potential applications. From prototyping and product development to education and medical applications, the possibilities seem limitless. As 3D printing continues to integrate into daily life, it transforms not only how products are created but also impacts the very nature of manufacturing itself.

In the following sections, we will delve deeper into my personal journey and experiences with 3D printing, exploring its vast potential and transformative impact on various fields.

My First Printer: Two Trees Bluer Plus

My journey into the world of 3D printing began with the acquisition of the Two Trees Bluer Plus. This printer stood out due to its commendable reputation within the 3D printing community, acclaimed for reliability and performance. Upon setting it up, I was immediately impressed by its user-friendly design and intuitive interface, which significantly eased my entry into 3D printing. The Bluer Plus proved itself capable of producing accurate and detailed prints, even during my initial attempts.

Throughout my exploration with the Two Trees Bluer Plus, I sought to understand its capabilities deeply, often challenging myself by pushing the printer to its limits. I began experimenting with various materials and settings, eager to grasp its full potential. There were moments of trial and error, but these experiences only fueled my passion for this innovative technology. The printer’s ability to handle intricate designs without compromising quality served as an affirmation of my investment. Watching my ideas materialize layer by layer was nothing short of mesmerizing.

However, no journey is without its obstacles. Occasionally, I encountered technical issues that threatened to derail my progress. During these times, the importance of reliable customer service cannot be overstated. My experiences with Two Trees’ support team were overwhelmingly positive, particularly the assistance provided by Mrs. Jeremy. Her prompt responses and constructive guidance made a significant difference, ensuring I stayed on track. Her expertise and patience transformed potential frustrations into valuable learning experiences, allowing me to overcome challenges effectively.

In retrospect, my introduction with the Two Trees Bluer Plus was not merely about acquiring a 3D printer; it was about embarking on a journey filled with discovery, creativity, and problem-solving. This initial experience laid a solid foundation for my future ventures in 3D printing, highlighting the critical role of good customer service in enhancing one’s proficiency with new technology.

Tronxy: A Love-Hate Relationship

My journey with the Tronxy XY3-SE printer has been nothing short of tumultuous, marked by both frustration and moments of triumph. Initially, the allure of entering the world of 3D printing with an affordable and feature-rich machine made the decision to purchase the XY3-SE feel like an exciting leap into innovation. However, as the weeks turned into months, the charm of this printer quickly began to fade, overwhelmed by reliability issues that plagued my printing experiences.

One of the major challenges I encountered was the inconsistency in print quality. Almost every print came with its own set of problems—layer misalignment, unexpected adhesion failures, and the occasional filament clogging seemed to become the norm rather than an exception. While I expected some degree of calibration and maintenance given the budget-friendly price point of Tronxy printers, what I ultimately faced felt more like a continuous struggle rather than an engaging hobby. The time spent troubleshooting issues often eclipsed the joy of bringing my creative designs to life.

Eventually, I found a suitable home for my Tronxy printer with a family member who expressed interest in exploring 3D printing. Passing it on allowed me to part ways with the frustrations while still encouraging another to embark on a creative journey. It is a testament to the complexity of 3D printing technology—a relationship filled with peaks and valleys but ultimately leading to a new chapter in both of our experiences.

The Persistent Zonestar Z8MP4

The Zonestar Z8MP4 has been a significant part of my 3D printing journey, characterized by numerous challenges that have tested both my patience and perseverance. From the moment I unboxed this printer, I encountered a variety of issues that hindered my ability to achieve consistent print quality. One of the major hurdles was the printer’s tendency to produce layers that were uneven, leading to prints that often required extensive post-processing or, in some cases, were completely unusable. This inconsistent output frequently compelled me to troubleshoot and refine my settings.

Among the solutions I attempted was the integration of Octoprint, an open-source application that allows for better control and monitoring of 3D printers. By utilizing Octoprint, I was able to remotely access the Zonestar Z8MP4, enabling me to adjust settings in real-time while a print was in progress. Moreover, this enhanced level of control allowed me to fine-tune the temperature controls and print speeds, which are crucial factors in achieving optimal print quality. However, despite these improvements, inconsistencies persisted, leading me to explore additional modifications.

In seeking to enhance the performance of my Zonestar Z8MP4, I also delved into implementing Klipper, a 3D printer firmware that significantly boosts print speed and quality. By optimizing the firmware settings, I hoped to address the mechanical limitations that plagued my printer. Each upgrade and adjustment was met with its unique set of challenges, requiring diligence and persistent efforts. As the journey continues, the Zonestar Z8MP4 remains a work in progress, pushing me to innovate and adapt, illustrating the broader experience many enthusiasts encounter in the evolving realm of 3D printing.

A Brief Encounter with Creality

In my exploration of 3D printing, I found myself drawn to the Creality Ender 3 Pro, a model that has garnered considerable attention within the maker community. Celebrated for its affordability and exceptional print quality, it has become a common choice for both novice and seasoned enthusiasts. Upon acquiring this printer, my initial excitement was palpable. The prospect of creating intricate designs and tangible prototypes sparked a surge of creativity and enthusiasm that I had long awaited.

As I embarked on my journey with the Ender 3 Pro, I was particularly impressed by the detailed resources and support available online. The community surrounding Creality is vibrant, filled with tutorials, modifications, and troubleshooting guides that seemed to make the learning curve less daunting. However, as I began to navigate the actual printing process, I encountered challenges that tempered my enthusiasm.

The printer’s finicky nature became evident almost immediately. From issues with bed leveling to the occasional filament jam, each print presented hurdles that required patience and persistence to overcome. While the machine’s capabilities were indeed remarkable, the frequent need for adjustment and calibration often led to frustration. This experience was a stark reminder that even the most popular devices can come with their own set of complexities.

Despite these challenges, my time with the Ender 3 Pro was not entirely disheartening. It provided invaluable lessons in troubleshooting and problem-solving within a 3D printing context. Although the initial excitement waned under the weight of technical difficulties, the printer ultimately fostered a deeper understanding of the intricate world of 3D printing. Through this journey, I realized that every challenge is an opportunity for growth, encouraging me to further explore this rapidly evolving field.

Anycubic: A Reliable Choice

Throughout my journey in the world of 3D printing, I have had the opportunity to explore various brands and models. However, my experience with Anycubic has been particularly noteworthy. After extensive research on different 3D printers available in the market, I determined that the Anycubic K3 Max was the right choice for my needs. It was crucial for me to find a printer that not only offered high-quality performance but also provided reliability, and I found that in the K3 Max.

The K3 Max boasts exceptional print quality and a user-friendly interface, making it suitable for both enthusiasts and professionals. During my initial setup, I was pleasantly surprised by its straightforward assembly process, which allowed me to start printing within a matter of hours. The printer’s stability during operation further solidified my confidence in Anycubic’s engineering and design. It has successfully printed a variety of complex designs without any issues, showcasing the impressive capabilities that have earned it a strong reputation in the 3D printing community.

Additionally, I eagerly anticipate the release of the K3 Max Combo, which promises to enhance the overall printing experience. This upcoming model has piqued my interest due to the anticipated improvements in build quality and features. As I prepare for this next step, I remain appreciative of Anycubic’s commitment to innovation and customer satisfaction. The company’s customer service has also left a positive impression, promptly addressing my inquiries and providing helpful recommendations to optimize my printing process.

In conclusion, my experience with Anycubic has set a high standard for what to expect in the realm of 3D printing. The blend of advanced technology, reliability, and strong customer support has made Anycubic a brand I can trust, and I look forward to continuing my journey with their products.

The Evolution of 3D Printing Technology

Over the past few decades, 3D printing technology has undergone a remarkable transformation. Initially, the concept was limited to industrial and research applications, utilizing complex and expensive systems that were not readily accessible to the average consumer. However, advancements in technology have made 3D printing more prevalent in various sectors, including healthcare, architecture, and even culinary arts. A pivotal factor in this evolution has been the drastic improvement in design software.

Modern CAD (computer-aided design) software has significantly simplified the process of creating 3D models. Many programs now offer intuitive interfaces and robust tools that allow users to design intricate objects effortlessly, catering to both novices and experienced designers. Furthermore, the integration of simulation and analysis features enables users to evaluate designs before committing them to the printer, enhancing efficiency and reducing waste.

In addition to software enhancements, improvements in printer hardware have played a crucial role in the evolution of 3D printing technology. Advances in printing techniques, such as FDM (Fused Deposition Modeling) and SLA (Stereolithography), have increased accuracy, speed, and versatility. Today’s 3D printers are capable of using a wider variety of materials, including metals, plastics, and bio-materials, which has expanded their applications significantly. These enhancements have made 3D printing solutions not only faster and more reliable but also more economical for businesses and individual users alike.

User-friendly features have also contributed to the rise in popularity of 3D printing. Many machines now come equipped with plug-and-play capabilities and touch screen interfaces, simplifying the set-up and operation process. Additional features like remote monitoring and integrated slicing software allow users to manage their printing tasks from anywhere, further streamlining the experience. As a result, the technology has become increasingly accessible to a broader audience, driving innovation and creativity in numerous fields.

Lessons Learned from My 3D Printing Journey

Throughout my experiences with various 3D printers, I have garnered several invaluable lessons that have significantly shaped my approach to this innovative technology. The first and foremost lesson is the critical importance of selecting the right printer for your specific needs. With a vast array of options available on the market, from budget models to high-end devices, it is imperative to conduct thorough research before making a purchase. Understanding the nuances of different types of 3D printers, such as FDM, SLA, and SLS, can help ensure that you choose one that aligns with your intended applications, whether they be prototyping, artistic projects, or functional parts.

Equally important is developing a clear understanding of personal needs and preferences. Before embarking on your 3D printing journey, it is essential to identify factors such as printing volume, desired material compatibility, and technical capabilities. Having a well-defined project scope can prevent the frustration that often arises from a mismatch between printer features and user expectations. For instance, aspiring designers may require a printer with advanced resolution and precision, whereas hobbyists might prioritize ease of use and affordability.

Another key takeaway revolves around the value of responsive customer support. No matter how reliable a printer may be, issues can arise, ranging from technical glitches to software complications. A manufacturer that offers accessible and effective support can make a significant difference in minimizing downtime. Engaging with a community of 3D printing enthusiasts can also be beneficial, as shared experiences and troubleshooting tips can aid in overcoming challenges more efficiently. Ultimately, these lessons highlight that success in 3D printing hinges not only on selecting an appropriate device but also on a holistic understanding of one’s individual needs and having robust support systems in place.

Recommendations for Newcomers to 3D Printing

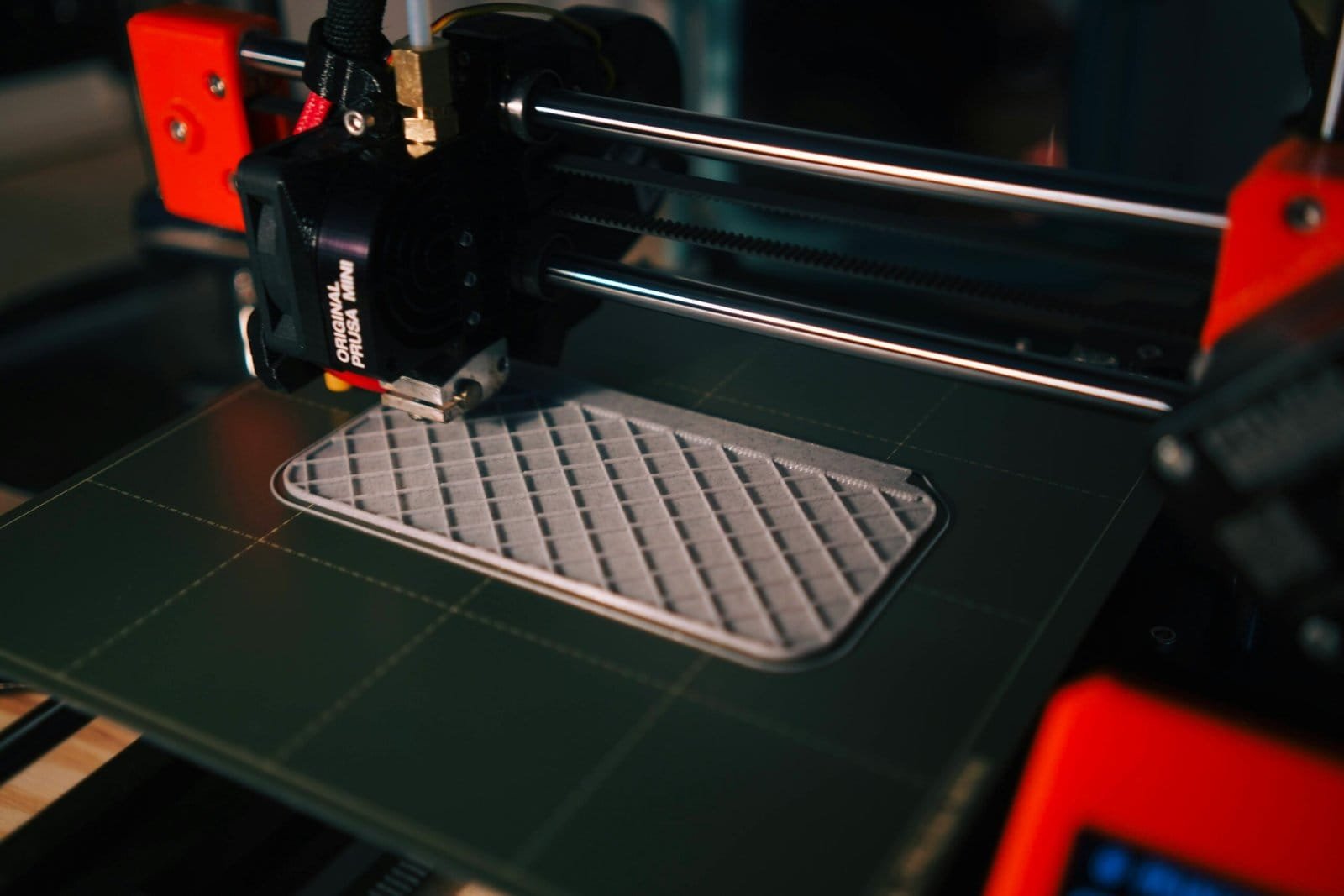

Entering the realm of 3D printing can be an exhilarating yet daunting endeavor for novices. One of the first and most crucial steps is selecting an appropriate printer model that meets your individual needs and budget. With a plethora of options available, it’s imperative to conduct thorough research before making a purchase. Beginner-friendly models, such as the Ender 3 and Prusa Mini, are often recommended due to their affordability and ease of use. These printers offer a strong balance between functionality and user support, making them ideal for those just starting.

Understanding the 3D printing community is another vital aspect of this journey. Engaging with forums, social media groups, or local maker spaces can provide invaluable support and insights that accelerate your learning curve. Websites like Thingiverse and MyMiniFactory serve as excellent resources for discovering free designs that you can print. By networking with other enthusiasts, you can acquire tips, troubleshoot common issues, and gain inspiration for your next project.

It is also essential to approach 3D printing with a mindset geared toward experimentation and problem-solving. As you embark on this creative journey, be prepared to encounter challenges such as print failures or calibration issues. Patience will be your best ally, as troubleshooting is a fundamental part of the process. Keeping a journal of your experiences can help track progress and identify recurring problems, making it easier to refine your techniques over time.

Additionally, consider investing in a reliable slicing software like Cura or PrusaSlicer, which can significantly enhance the quality of your prints. Lastly, partake in continuous learning by watching tutorials or attending workshops. Knowledge is power in this fast-evolving field, and being well-informed will help you navigate the complexities of 3D printing while fostering your creativity.

Conclusion: The Future of 3D Printing

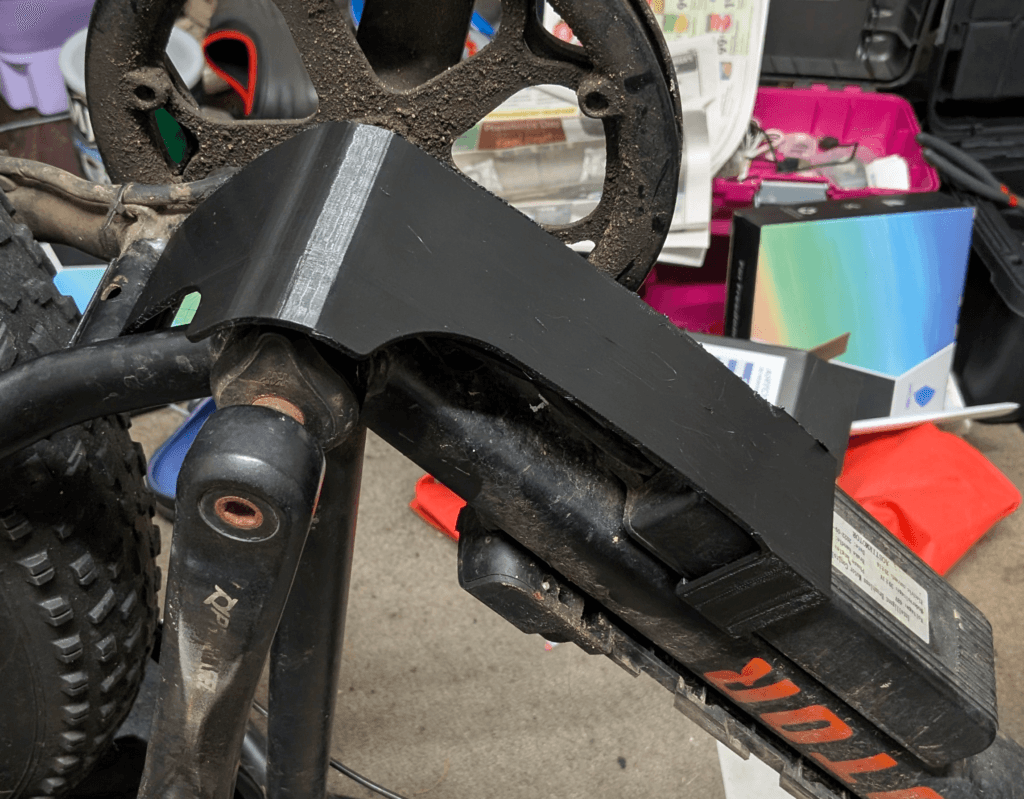

As I reflect on my journey through the realm of 3D printing, it is evident that this technology is not merely a passing trend, but rather a revolutionary force that holds immense potential for the future. My firsthand experiences with various printers have reinforced the idea that 3D printing can fundamentally transform industries, enhance creativity, and provide practical solutions to complex challenges. From prototyping new products to creating customized items, the applications of 3D printing are seemingly limitless.

In the coming years, we can expect significant advancements in materials, speed, and precision, which will undoubtedly push the boundaries of what can be achieved with 3D printing technology. New innovations are on the horizon, such as bioprinting and construction printing, which will expand its utility even further. Furthermore, as sustainability becomes a growing priority, 3D printing may offer environmentally friendly alternatives to traditional manufacturing methods by reducing waste and enabling the use of recyclable materials.

Throughout this journey, I have consistently engaged with Anycubic printers, which have proven to be reliable tools. The support and resources provided by Anycubic significantly enhance the user experience, making it easier for both amateurs and professionals to navigate the complexities of 3D printing. For those considering entering this innovative space, I wholeheartedly recommend exploring the offerings from Anycubic. Their commitment to quality and user satisfaction is evident, and their printers can serve as excellent starting points for anyone eager to dive into 3D printing.

In conclusion, the future of 3D printing is bright and full of promise. By embracing this technology, we can harness its potential to drive creativity, sustainability, and efficiency across multiple sectors. I encourage readers to keep an eye on developments in this field and to consider how 3D printing may impact their personal or professional lives. The journey has just begun, and I am excited to see where it leads us.

Have a Character or Desk Ornament you want Printed? Check Out Our Print Estimator. Best Priced Prints on the Web! Adding more Features regularly!

Leave a Reply

You must be logged in to post a comment.