3D Printing Business Expectations are in!! 2025

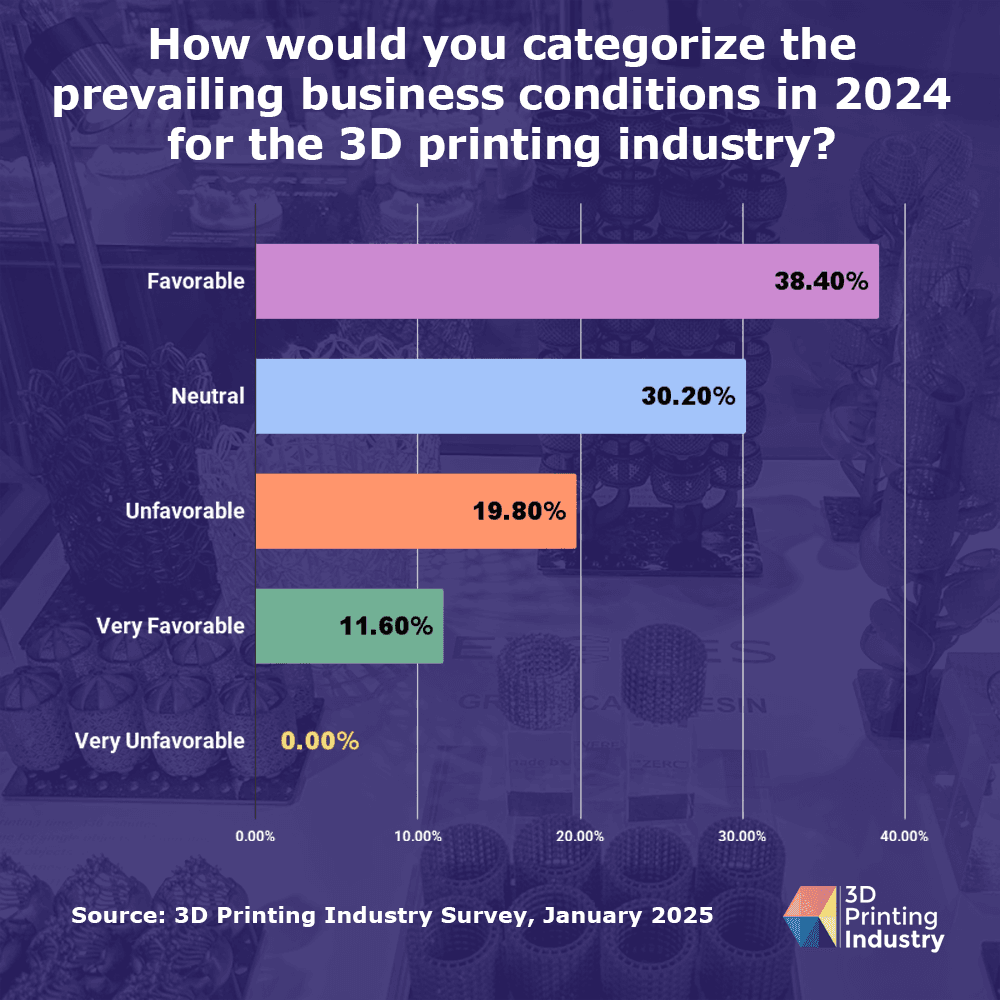

Ever wonder how all these “New” 3D Printing Companies sprout up and appear to be doing so well. That’s called “Marketing”. Better known as “fibbin”. This chart to the left clearly shows how the “Industry Leaders” felt last years business was. Clearly nobody, not 1% felt it was “Very Favorable”, which is ok, as none said it was “Very Unfavorable”. Nobody went out of business, but almost nobody made millions either. Of course there are companies out there that did and will again this year.

1

Evidence to keep those small businesses going to there! Overall, Favorable is gaining ground. Now this is a “Prediction” obviously. The full article can be read Here. The rest of this article will relate to the info there, but this is my take on how “small” 3D Printing Companies will do, and what it will take for them to succeed. So with that, lets get right into the important stuff.

The market or industry conditions may have introduced uncertainties affecting both business and operational environments.

I want to touch on this likely the most. 3D Printing is fairly new to the “Hobbyist” world. In other words. It’s only been a few yrs since 3D Printers have become affordable enough for common folk to get their hands on them. Industrial 3D Printing has been around and in use for 40 plus years. These Printers were produced to do one or two applications, not keep a creative hobbyist busy.

In other words. These “Uncertainties” are likely to continue. In 3 years time, I’ve seen printing go from, “Slow Aggonizingly Painful Failures” with little to no “Color”. To an array of Color, toppled by speeds. 3 Years ago, a slow multi-material printer would cost you $1200 or more. If they were multi-material, they gave up something else, such as print area size, or in many cases a few years ago, they just didn’t work without constant attention.

In short, as usual. You can thank the “Open Source” community that loves to create things for the Constant push to upgrade and make better the tools we use.

Quite a few companies stepped up to all the challenges this rapidly changing and diverse industry, bringing us faster printers, then colorful printers, then even combining those two things with, yes as the article points out. “More confidence in business and operational conditions.”. With larger, more colorful, and faster printers. With a success rate of 90% or better per print, vs. 2 yrs ago (60%).

Here’s What We Think!

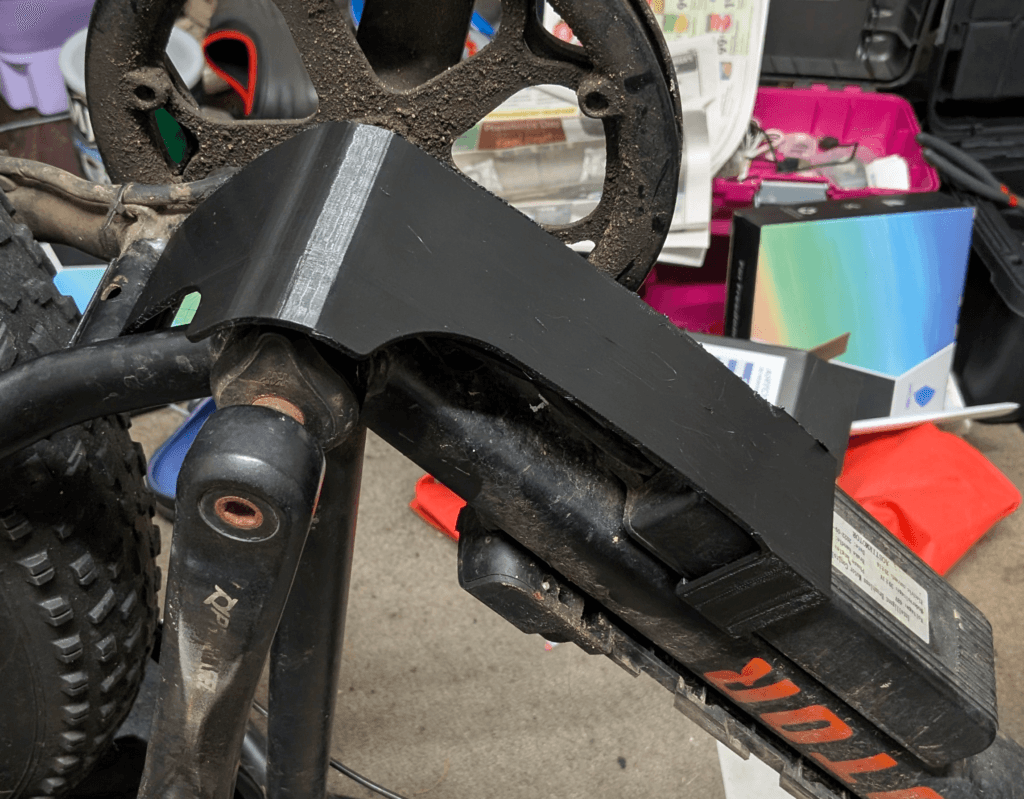

Small 3D Printing Businesses like HoodBilly Haven. Will need to remain vigilant! Keeping up with “All” the trends of Prining. Yes, all! I’m just going to use Slant 3D as an example of a possible mis-step in this industry. They’re likely not alone in their move a few years back, and maybe it has been profitable. Here’s what I see though. A ton of not “Obsolete”, but also by no means “Capable” either, Machines. Even fast, super fast. Single Material Printers are good for soft materials, and prototypes. They won’t be sufficient in the “Decretive Sector” of the 3D Printing Industry. Which brings up “Diversity”. By my 2nd printer. I saw things moving fast. When I started printing. Everything was running RepRap, or Marlin Firmwares. There wasn’t much they were doing differently then. RepRap broke into multi-material first I think. It’s hard to remember how it all played out. Ton of printers, from “homebrewed” (Voron, RepRap, more) to every company with alittle money to blow, jumpin in to make a buck. The scene was chaos! Thenn came Klipper! I stopped buying printers, and started asking companies questions. Not specs of their current machines, but where they were taking that machine next!

Conclusion!

This year is going to bring more “uncertainty” to the plate with more upgrades to these features. More colors, by end of 25. 32 Colors at a time will not be “unheard of”.

Speed? Let’s face it we’re at a point where you can’t properly melt and cool the filaments (with good layer adhesion) as fast as the machine can move. Which causes “flawed” prints. Even when they look good, they may not be “good”. Speed I think has reached it’s peak. But rest assured, someone will try!

Materials: Materials are going to be ever changing. From the “quality” of the material to the “Coatings” it can carry. I would really like to see advancement in soft materials, and I think there will be some, but it is not the direction we’re headed.

Ok, here’s the big one. Little Guys! Desktop Metal is here! If you want to stay diverse and capable in the industry. Invest in Metal Printing this year! Don’t go “Huge”, these things are just getting started.

Stick with companies that have been in the industry, and really watch companies like Tronxy. They’ve been making diverse printing machines for some time. From desktop fdm, to concrete & clay printers. Smaller manufacturing companies with this sort of diversity, could take advantage of this years breakout into Metals.

I’m going to push AnyCubic towards full metal printers. They have a “Mixed Material” printer that never really appeared to take off. I’m not sure it’s still on their website as I write this. What I can vouch for is their dedication to the industry and their unwavering customer support!

Sign Off!

As always. Thanks for reading! Please comment, criticize, or compliment. Let us know how we’re doing, and what you’d like to see next! Use our ever growing (not done) list of Affiliates to save yourself a buck and support the Haven at the same time. Try out our Haggle Feature! Best “Name Your Price Tool” on the web! And of course don’t forget about Our 3D Design & Printing Services! Best way to get exactly what you want, is to tell us exactly what it is. Use our forms, emails, or phone to contact us. Try our Estimator for an excellent pricing guide!

Our Affiliates

Quotes, Comments, & More!

Get Creative with HoodBilly Haven!

Don’t settle for ordinary! Let HoodBilly Haven create a one-of-a-kind design just for you. Use the form below or call/text us at +1(906) 239-4316 to get started.

Leave a Reply

You must be logged in to post a comment.